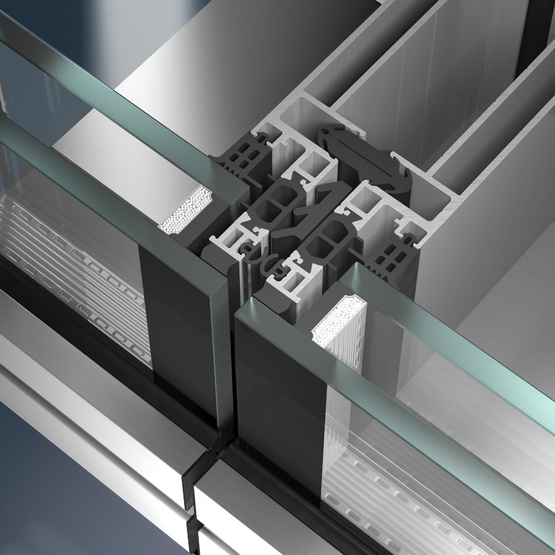

Unitised curtain wall with high level of cost-effectiveness, functionality as well as an attractive appearance – and façade bracket for universal load connection

The design of the Schüco Façade USC 65 (Unitised System Construction) is flexible and can be fabricated efficiently. With its all-round narrow face width of only 65 mm as well as maximum unit weights up to 500 kg, it enables large architecturally appealing façade constructions. An additional benefit: with the façade bracket made from glass fibre-reinforced plastic, loads such as solar shading systems can be connected safety and without thermal bridges. The approval is pending for this energy-efficient solution, which is free of condensation, on the basis of numerous tests.

With its three design options, Schüco USC 65 offers maximum design freedom to create highly sophisticated architecture: Schüco USC 65 F as unitised façade with framed look, Schüco USC 65 FSG in structural glazing look with horizontal or vertically arranged glazing beads.

For using opening units in unitised façades, there is a wide range of Schüco windows from the AWS to the super-insulated Schüco AWS 114 SG.SI series.

Energy

- Different lengths of insulating bar with Uf values of 1.4 W/(m²K) to 2.9 W/(m²K) for variable adjustment to different thermal insulation requirements

Design

- Continuous narrow face width of 65 mm; glass thicknesses between 4 mm and 16 mm for single glazing and between 16 mm and 56 mm for double insulating glass

- Design variants for frame appearance and semi-structural glazing

- All opening types can be implemented – from inward-opening turn/tilt vents to outward-opening projected top-hung or parallel-opening vents

Automation

- Integration of Schüco AWS 114 as projected top-hung window or parallel-opening window: possibility of large automated window solutions incorporated in the building management system for standard and SHEVS applications

- Insert outer frame profiles for integration of the Schüco AWS window series with Schüco TipTronic fitting

Security

- Comprehensive system tests in accordance with European and American test standards

- Burglar resistance tested in the system to RC 2

Enhanced function

- Large unit dimensions and heavy unit weights of up to 500 kg possible

- Integration of a broad range of Schüco windows possible

- Two horizontal joint gaps for variable adjustment to different roof deflections: 10 mm to accommodate a ± 5 mm stretch and 20 mm to accommodate ± 7.5 mm stretch

| System / Material | Aluminum |

| Energy | Highly thermally insulated |

| Façade type | Unitized façade |

| Uf value (>=) | 1.4 |

| Min. face width | 65 mm |

| Approvals Burglar resistance | RC2 |

| Air permeability | A3 |

| Watertightness | RE1200 |

| Impact resistance | I5 / E5 |

| Safety barrier loading | Fully suitable for safety barrier loading |

| Surface finishes | TopAlu / Decorative foils |

| Wind load resistance | <= Zull 1,5kN/m² erhöht 2,25kN/m² |

PREVIEW SPECIFICATION

Schüco USC 65.HI, highly thermally insulated, self-supporting, unitised aluminium façade system

As a unitised façade for multi-storey façades with external glass retention frame or alternatively with SG bonding on 2 sides and retention frame on 2 sides for horizontal or vertical emphasis of the façade, load-bearing structure on the room side with 65 mm face width (unit joints and glazing bars).

Design features (façade load-bearing structure):

The construction must have HI isolators to suit the infill thicknesses.

The load-bearing structure of the façade construction consists of right-angled, multi-chamber hollow profiles in unitised construction, using corner cleats with Schüco adhesive injection and bonding technology, mitre-cut, optionally with sash bars, inserted using T-cleats and seals with integral sealing channels for sealing the H-joints. The load-bearing profiles with a basic depth of 125 mm or 150 mm are arranged on the room side and have a continuous inside and outside face width of up to 65 mm. All profile edges are rounded.

Max. dimensions 2700 x 3600 mm, unit weight up to 500 kg.

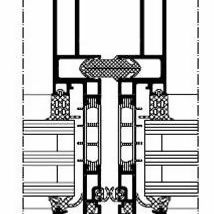

Coupling of units:

The horizontal units are coupled using a special coupling/saddle gasket made from microcellular rubber, which must be inserted in the gasket locating grooves of the frame profiles. The vertical units are coupled using fixing lugs, which are part of the unit hanging brackets, and using horizontal gaskets. The coupling joints for the gaskets must overlap; the vertical coupling gaskets overlap the horizontal gaskets (saddle gasket and horizontal coupling gasket). When installing the units, the horizontal continuous saddle gasket must be sealed. A front chamber gasket to take up tolerances must be incorporated in the saddle gasket described above. The external glazing bead is fixed in place by means of a screw or, alternatively, by means of a PE cord in sections. The inner frame profiles and the all-round outer glazing beads receive a colour coating as described in more detail in the section on surface finishes.

The horizontal butt joint (= vertical size between two façade units one above the other) can take up tolerances, e.g. as a result of ceiling movements, of ± 5 mm or alternatively up to ± 7.5 mm (2 options for respective gaskets).

Design features (fixed glazing, frame solution):

Single or double glazing, glass thickness 22 to 56 mm with Thiokol edge seal can be used. The insulating glass is fixed mechanically using continuous, mitre-cut glazing beads.

The glazing beads can therefore be designed as a flat glazing bead, U-shaped glazing bead or L-shaped glazing bead. The panes of insulating glass are fixed and sealed using EPDM glazing rebate gaskets on the room-side to the outside. All glazing, even in the insert units, lies in the same plane.

Design features (fixed glazing for vertical emphasis of façade):

Stepped insulating glass (steps on 2 sides) between 32 to 56 mm thick with a silicon edge seal can be used. The units must be glazed by the customer.

The insulating glass is fixed mechanically to the frame profile vertically on two sides using glazing beads and horizontally on two sides using the bonding of the stepped insulating glass.

The glazing beads can therefore be designed as a flat glazing bead / U-shaped glazing bead / glazing bead with tapering face width / L-shaped glazing bead. All glazing, even in the insert units, lies in the same plane.

Design features (fixed glazing for horizontal emphasis of façade):

Stepped insulating glass (steps on 2 sides) between 32 to 56 mm thick with a silicon edge seal can be used. The units must be glazed in the factory. The double glazing is mechanically fixed on the two horizontal sides using glazing beads and on the two vertical sides by bonding the stepped unit to the frame profile. The glazing beads can therefore be designed as a flat glazing bead / U-shaped glazing bead / L-shaped glazing bead. To cover the horizontal butt joint, a flat cover cap can be used horizontally, which covers the glazing beads and the butt joint between two units one above the other. All glazing, even in the insert units, lies in the same plane.