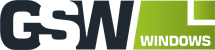

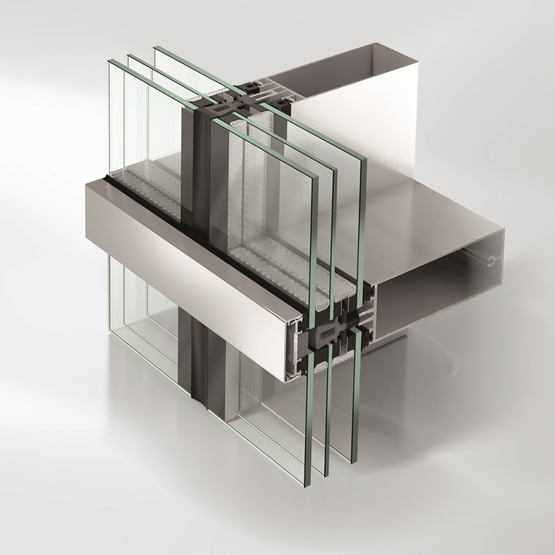

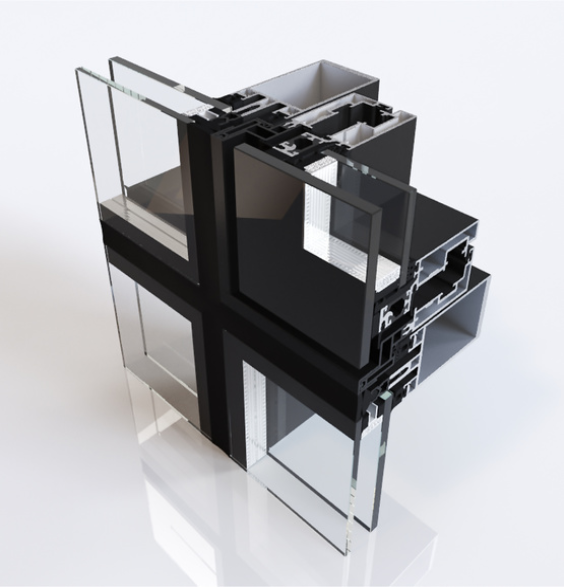

Elegant all-glass façade with low thermal transmittance to passive house standard as well as large units with triple or double glazing – solutions for the building envelope, which are high-quality in terms of both architecture and technology

The profiles that are only visible on the inside lend the external façade a flush-fitted all-glass look with slender joints. Highly thermally insulated isolators, pre-fillers and triple insulating glass ensure very low Ucw values up to passive house standard.

The system also allows the façades to be designed in a semi-structural glazing look.

The Schüco AWS 114, AWS 114 SG, AWS 114.SI and AWS 114 SG.SI insert units fit seamlessly with the appearance of the all-glass façade. They can be operated manually or with Schüco TipTronic as outward-opening projected top-hung windows or parallel-opening windows.

Energy

- Specially developed, stainless steel spacers which can be processed by machine for airtight edge seal

- Highly thermally insulated SI isolators as well as pre-fillers for very good thermal insulation

- Aluminum spacers for low to medium thermal insulation requirements

Automation

- Integration of Schüco AWS 114 as projected top-hung window or parallel-opening window: possibility of large automated window solutions incorporated in the building management system for standard and SHEVS applications

Security

- Tested as suitable for safety barrier loading with slimline stainless steel retaining clips, aluminum retaining clips and clip rosettes

- RC 2 burglar resistance

Enhanced function

- Structural glazing façade for double and triple glazing with maximum glass dimensions (W x H) of 2600 mm x 4200 mm (in accordance with general building authority approval); glass thicknesses of 32 mm to 64 mm; pane weights up to 650 kg possible with new cruciform glazing supports

- Plastic pocket profile as cost-efficient alternative to fixing cleat

| System / Material | Aluminum |

| Energy | Thermally insulated |

| Design | Structural Glazing |

| Façade type | Transom-mullion |

| Uf value (>=) | 1.4 |

| Min. face width | 50 mm |

| Approvals Burglar resistance | RC2 |

| Air permeability | Class 4 |

| Watertightness | RE1200 |

| Safety barrier loading | Fully suitable for safety barrier loading |

| Surface finishes | TopAlu / Decorative foils |

| Wind load resistance | Permitted load (<=) 2.0 kN/m²; increased 3.0k N/m² |

PREVIEW SPECIFICATION

Schüco FW 50+ SG, thermally insulated self-supporting aluminium façade system “without external cover caps and glass pressure plates, option with gas-tight (EN 1279, Part 3) or airtight (EN 1279, Part 2) pane edge joint”

As a mullion/transom construction for multi-storey façades with an internal and external face width of 50 mm

Approval:

Planning, calculation and design must be in accordance with the conditions of the general building authority approval, approval number Z-70.1-46, and/or European Technical Approval (ETA), approval number ETA-05/0114. Designs that differ from the general building authority approval / ETA require project-specific approval from the respective supreme building authority.

Load-bearing structure:

The load-bearing structure of the façade construction consists of rectangular multi-chamber hollow profiles.

The load-bearing profiles are on the room side.

All profile edges are rounded.

The transom profiles are notched and overlap the mullions where they intersect, so that any moisture is reliably drained away.

On multi-storey façades, all horizontal joints must be constructed using the joint connectors and joint tolerance seals belonging to the system.

Appropriate system-based aluminium insert profiles and half profiles, as well as expansion joint seals, must be used for vertical expansion and assembly joints.

Up to 8-metre installation height, without mechanical fixing; > 8 metres, with additional mechanical fixing

Glazing / insert units:

In the production of double glazed units, a pane of heat soaked toughened safety glass is used on the outside.

The insulating glass is mechanically fixed to the structure of the façade using screw-in glazing clips which are inserted into the pane edge joint between the double glazing panes.

The maximum distances between supports of the clips are calculated in accordance with the tables and fabrication information provided by the system manufacturer.

Depending on the pane composition and when using reinforced glazing supports in conjunction with aluminium or steel insert profiles and heavy duty T-cleats, glass loads of up to ____ kg can be transferred per pane field (see the fabrication documentation from the system manufacturer).

Storey-height glazing with safety requirements in accordance with TRAV must be secured individually with additional glazing clips.

The remaining 20 mm wide joint between the glass edges is closed with a PE filling tape and sealed with silicone sealant: DOW CORNING, DC 795/DC 797 – SIKA AG, Elastosil 600/605.

Ventilation:

The façades must be designed according to the principle of overall ventilation. From a unit height of 8 metres or 8 fields, the rebate base must be ventilated. For transom lengths > 1500 mm, there must be additional ventilation in the centre of the field.

Profile face widths:

Mullion, transom 50 mm

Profile basic depths:

Mullion 125 mm

Transom 130 mm