Passive-house certification for add-on construction on steel (ST) and timber (TI) with outstanding performance characteristics

With the façades systems, skylight constructions and large vertical façades are easy to manufacture to passive house standard. The Uf values of the system construction on steel and timber are as low as 0.8 W/(m²K) (including screw factor) and match the stringent requirements of the Passive House Institute in Darmstadt.

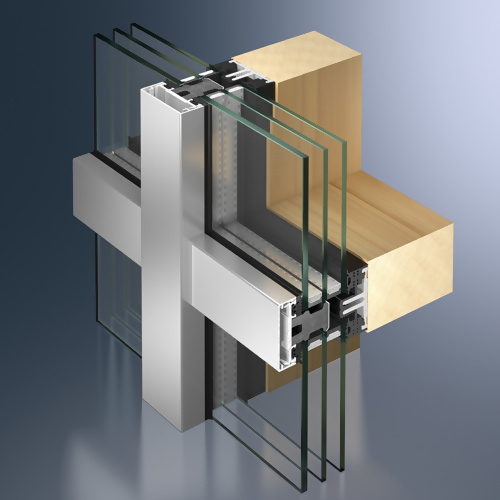

For triple glazing in particular, large pane dimensions can be accommodated easily for the add-on construction in terms of load transfer and screw guide owing to innovative and patented system articles.

In the sensitive roof area in particular, the innovative sealing system ensures maximum thermal insulation with optimised fabrication thanks to an integrated screw guide.

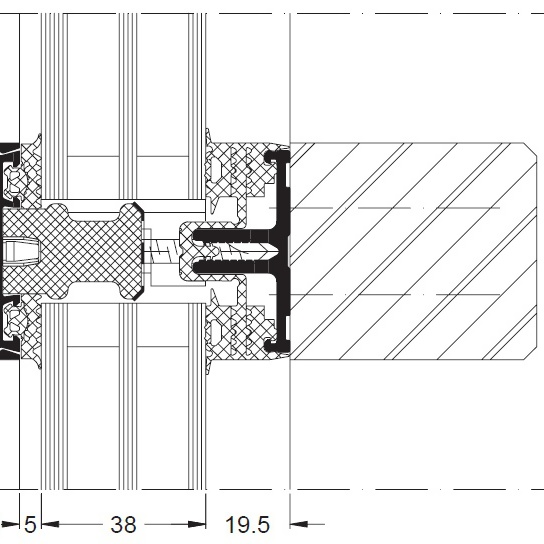

The Schüco AOC add-on construction with 50 mm and 60 mm system widths on steel (ST) and timber (TI) combines energy-efficient construction with efficient fabrication and installation.

- Add-on construction in system widths of 50 mm and 60 mm on steel and timber for glass roofs and vertical façades

- Passive house-certified thermal insulation for vertical façades and roof area

- Three drainage levels for maximum design flexibility

- Large glass loads up to 11 kN for steel and 7.3 kN for timber are possible with system articles

- Compatible with Schüco Window and Façade Modules ProSol and ProSol TF

| System / Material | Aluminum |

| Energy | To passive house standard |

| Design | Timber look |

| MISE EN ŒUVRE | Structure bois |

| Façade type | Add-on construction |

| Uf value (>=) | 0.77 |

| Min. face width | 50 mm |

| Approvals Burglar resistance | RC2 |

PREVIEW SPECIFICATION

Schüco AOC 50+ TI, thermally insulated aluminium add-on construction on a timber load-bearing structure (gasket system)

As a mullion/transom construction for multi-storey façades with a 50 mm external face width.

Design features:

The construction must be sealed from outside using aluminium pressure plates to suit the infill thicknesses.

Load-bearing structure:

Selection

The load-bearing structure of the façade construction must be fabricated from suitable types of wood.

Or

The load-bearing structure of the façade construction is to be fabricated from suitable types of wood supplied by the customer.

End

Wood quality, design and surface treatment are described separately. The necessary cross sections must be calculated according to DIN 1052. Furthermore, DIN EN 942 (Wood in joinery work), DIN 1055 (Anticipated loads for buildings) and “Technical regulations for the use of glazing with linear supports, DIBt, September 1998 edition” must be taken into account in the design of the construction. The load-bearing wood construction is on the inside. In faceted façades, the width of the wood profile must not exceed 60 mm if insert units are planned to be installed.

The glazing system consists of aluminium cover caps and/or pressure plates (clamping connection). The joint between the pressure plates and the load-bearing structure must be designed in accordance with the conditions of the existing general building authority approval. The glazing system is attached to the load-bearing structure using an aluminium basic profile by means of screw connections. The aluminium profiles have alternating holes 125 mm apart for this purpose. A large-volume EPDM gasket with integral ventilation channels, structural height 15 mm, forms the basis for the installation of the glazing and the ventilation of the construction. The joints of the gaskets to be laid horizontally and vertically must overlap and be sealed. The corresponding alternating notches must be made in accordance with the system manufacturer’s recommendations.

Glazing / insert units:

All glazing, even in the insert units, lies in the same plane.

The glazing gaskets made from weather-resistant, black EPDM on the room side are of different depths in the mullions and transoms (6 mm offset).

Two individual gaskets made from weather-resistant, black EPDM, with a height of 5 mm, are positioned on the outside. Moulded gasket intersections made from EPDM must be used where mullions and transoms join.

Ventilation:

Rebate base ventilation and vapour pressure equalisation are achieved at all four corners of each module field into the mullion rebate.

For field drainage and ventilation, appropriate openings must be made in the aluminium pressure plates, cover caps and gaskets.

Dimensions and design of the exterior cover caps:

Cover cap (mullion) U-shaped 50 x 30 mm

Cover cap (transom) rectangular 50 x 8.5 mm