Designers, architects and appliances industries have discovered the flexibility and usability of ceramic ink printed glass. Just look at how creative minds have brought brilliant ideas to life on building exteriors, interior glass and all manner of glass projects all with unmatched sustainability.

GSW Digital Ceramic Glass can really help bring your design to life with our cutting-edge printing facilities.

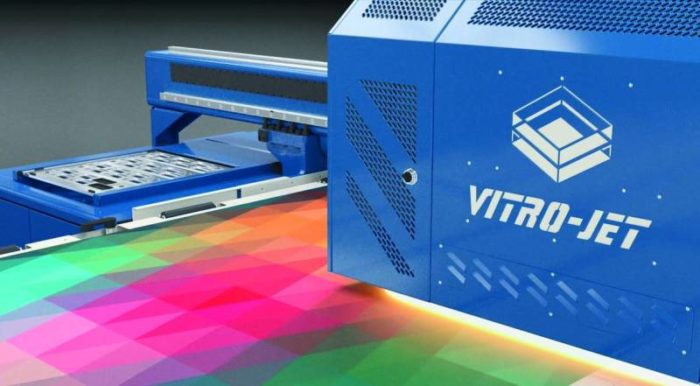

We employ the latest ceramic printing machinery, Vitro Jet F Type, which is among the largest in the glass industry and have the ability to incorporate bespoke designs and motifs onto your glass. Each and every design we produce is unique to our clients.

Our glass printing is state-of-the-art: the glass is heated to fuse the ink onto the surface, producing a final product that is extremely durable and very stable against UV degradation and surface chemicals. This makes it suitable for many different applications in architectural , and security markets. For structural glass, such as flooring, we can also design custom frit patterns for anti-slip features.

For more complex printing, GSW Glazing have the capability and the know-how to provide a printed PVB film inter layer which is then laminated into two or more layers of glass. This type of printing allows an exceptional level of detail that completely protected from the external environment.

Vitro Jet F type

The highest quality at the highest speed

THE PROCESS

Image Processing

Our team gets the designs ready to be transferred from standard graphic files to a ready-to print image using Tecglass, which makes every printing job a creative project that is easy to set-up and process.

Glass Preparation

The glass is washed and prepared for printing.

Digital Printing

The prepared glass is loaded and positioned on the Vitro Jet F Type glass printer.

Drying

A built in dryer dries the ceramic ink that was printed on the glass.

Tempering

In-line conveyors transfer the glass into the tempering furnace, where the digital ceramic inks are fused permanently into the glass for unmatched performance and durability.

Benefits

In the face of global warming and rising costs, architects, developers, and consultants are increasingly seeking sustainable and green materials. Digital ceramic printed glass is a material that is Eco-Friendly and also provides functionality and endless design possibilities, making it an ideal material to support sustainable architecture.

GSW Glazing shares the top twelve ways that they work with digital ceramic glass.

Unmatched Resistance

To scratching, acid, UV light and weather.

Heavy metal-free-inks

Do not contain Lead or Cadmium.

Widest vivid color gamut

Mixed digitally or manually.

Compliant with demanding industry standards

For quality and durability.